Paracatu’s Predictive Maintenance teams at Plants I and II are upping their game when it comes to detecting electromechanical failures. Nine employees recently took part in 40 hours of thermography training to enhance their skills in detecting these failures at site.

Thermography, which uses infrared radiation to map heat distributon, is an important tool in predictive maintenance because it can accurately determine the condition of in-service equipment. The team can find out when maintenance should be performed in real time and without ever having to shut down the equipment. This leads to less downtime for maintenance because it is only performed when necessary and parts are only replaced when needed. It also leads to cost savings because tasks are performed only when warranted.

Thermography’s other benefit is improved safety because inspecting equipment does not require direct contact. It also makes it possible to reach hard to access places in machinery, like panels, transmission lines, coated pipes, etc.

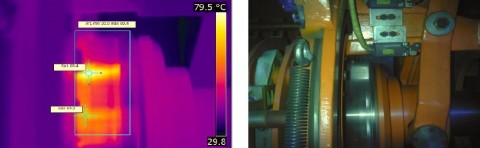

A good example of thermography at work was when the team inspected the mill at Plant 1 and found that parts of the mill ring had abnorally high temperatures of around 128.2°C. Thermal imaging allowed the team to pinpoint the problem and they performed the needed maintenance. The team was then able to monitor the mill ring and get it down to 33.8 °C, a more normal temperature range.

The thermal imaging not only allowed for maintenance at the right time, but it also made the mill safer and will allow the team to use the mill ring longer.

“We are glad to have taken this course. Our team has been using thermography for a while, however, with the training, we will be able to use the technique more efficiently, especially in the early detection and analysis of electromechanical failures,” said Diego dos Santos Teixeira, Inspection Technician, PI Predictive Maintenance, Paracatu.