Unless you’ve been sleeping under a rock for the past few years, you know that Kupol is remote. Like remote in the sense that it’s on top of the world – at the Arctic Circle. Not exactly the easiest place to get people or supplies to.

Most of the cargo needed to run the mine (equipment, food, tools, machinery, replacement parts, linens, office supplies, toilet paper…everything)…arrives on ships loaded with cargo containers at the Port of Pevek, a port village on the Arctic Ocean. The containers are hauled a few hundred kilometres to Kupol – along an ice road we build ourselves every year.

That means Kupol has a LOT of cargo containers onsite at any given time. Upwards of 7,000. (It’s not worth it from a cost perspective to ship all of the containers back, so some essentially become our property, with many being used for onsite storage and warehousing.)

And leave it to the always-ultra-creative Kupol team to come up with ingenious ways of putting the unused containers to good use.

Today Kupol is using empty containers to build buildings, add additions to buildings, construct bridges, form walls to protect stockpiles, create indoor greenhouses to grow fresh produce, and in their latest venture…as pillars (i.e. ground support) in underground mine shafts.

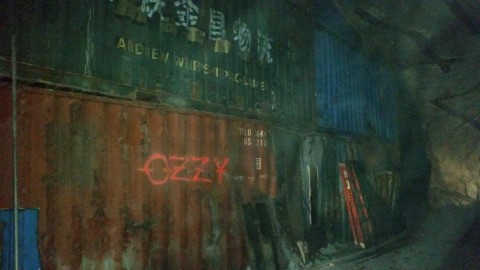

Shipping containers filled with cement are being used as underground pillars at Kupol

Shipping containers filled with cement are being used as underground pillars at Kupol

The containers are moved underground using hauling equipment, and welded to reinforce the edges. The top is cut open and filled with cement. Once filled, they weigh 60 tons. Then another container is installed on top and welded to the first. Then it’s pumped full of cement too. After that, they’re resealed using foam.

“Installation of concrete-container support pillars saves us lots of time, labor and costs. An idea like this is innovative and adds value to our business,” says Timur Mamatyusupov (Deputy Chief Engineer). “We’ve never heard of anyone else in mining or any other industry doing this.”

“This is an excellent way to re-use our storage containers, and another example of the innovation and creativity of our team here at Kupol,” says Dave Neuberger (General Manager, Kupol).

Timur Mamatyusupov (Deputy Chief Engineer, Kupol)

Timur Mamatyusupov (Deputy Chief Engineer, Kupol)

Fresh lettuce grows in a shipping container-turned-hydroponic-greenhouse at Kupol

Fresh lettuce grows in a shipping container-turned-hydroponic-greenhouse at Kupol